The eco-design of a product, service or production system is a major means of reducing environmental impact at source. Ecodesign aims to integrate, right from the design stage of a product, the ecological consequences of its manufacture at every stage of its life cycle: extraction of raw materials, production, distribution, use and end of life. 80% of a product’s environmental impact is determined during the design phase. Construction, mechanical engineering, chemicals, furniture, textiles and packaging are the main industrial sectors developing eco-designed products.

In concrete terms, eco-design can result in savings in materials (through weight reduction) or energy consumption, optimized supply chains (truck fill rates, cold chain), or reduced quantities of waste to be processed. The transition from multi-material to single-material design is also a key aspect of eco-design: a single material means simplified sorting and easier recycling.

For example, a major charcuterie brand has replaced the different types of plastic used in its ham trays, making them single-material and easier to recycle. Another example is these 100% compostable tea bags, made entirely from wood pulp from sustainably managed forests, without labels, string or staples.

The French General Commission for Sustainable Development (CGDD) estimates that reductions in the environmental impact of an eco-designed product are usually between 10 and 40% on a dozen indicators. The reduction in environmental impact can be as much as 70% for certain consumer goods.

AFAQ Eco-conception recognizes your approach

In an eco-design approach, the analysis of environmental impacts is based on various criteria: contribution to climate change, pollution and nuisances, soil erosion, acidification of the environment, biodiversity… A global method that requires a thorough mastery of the Life Cycle Assessment (LCA) exercise, and which fully integrates eco-design into a circular economy approach.

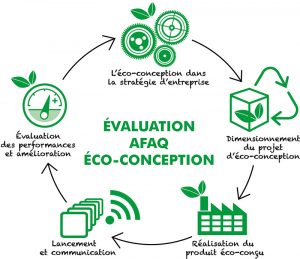

To lend credibility to its involvement with consumers and stakeholders, a company can have its eco-designed products certified by a product certification body (NF Environnement, European Ecolabel). It can also opt for the AFAQ Eco-conception assessment, which focuses more on project management than on the end result, and thus demonstrates the effort made in terms of organization and resources in the eco-design process. The AFAQ Eco-conception assessment takes the form of a score out of 1,000 points, reflecting a maturity scale, awarded following an independent assessment. You can download

the AFNOR Certification guide

which describes the process in detail. Finally, it’s good to know that SMEs and VSEs taking their first steps in eco-design can benefit from financial assistance under ADEME’s Tremplin scheme, backed by the stimulus plan.