Implementing an energy management system (EMS) in line with ISO 50001 can help identify often unsuspected sources of energy savings. And in so doing, contributes to improving the organization’s environmental performance.

The fight against climate change is a cornerstone of the ecological transition. Limiting temperature rises to 2°C by 2100 means phasing out fossil fuels and replacing them with renewable energies. Yet these still account for only 14% of final energy consumption in France. In the meantime, it is imperative to improve the energy efficiency of equipment, processes and buildings: we need to consume less for the same service.

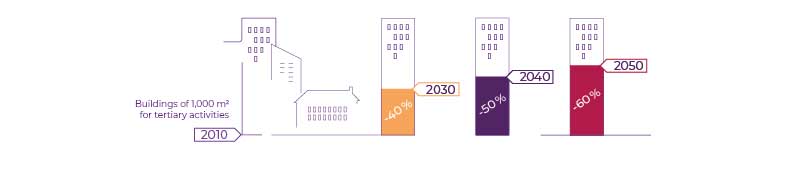

European regulations require companies with over 250 employees or sales in excess of €50 million to carry out energy audits every four years. At the same time, the 2018 ELAN law requires occupants of 1,000 m² buildings housing tertiary activities to save 40% energy by 2030 compared with 2010, then 50% by 2040 and 60% by 2050.

Choosing and building your environmental performance indicators

The GHG Protocol (Green House Gas Protocol) is the oldest standard for accounting greenhouse gas (GHG) emissions. It served as the basis for NF EN ISO 14064 ” Quantification and reporting of greenhouse gas emissions for organizations “. It distinguishes three main groups of indicators along the supply chain:

- direct emissions (scope 1) ;

- emissions associated with the production of imported or purchased electricity, heat or steam (Scope 2);

- emissions resulting from the company’s own activities, but originating from suppliers (scope 3).

To help you get up and running, we strongly advise you to set up an energy management system (EMS). This methodical management focuses above all on energy sobriety and efficiency, according to the adage: “The best energy is the energy we don’t spend. The application of voluntary standard ISO 50001 facilitates this exercise, as it explains how to organize yourself to ensure that energy savings materialize over the long term. The text was revised in 2018 to reflect the state of the art in collecting consumption data and measuring energy performance improvements.

Energy management: quantifiable results thanks to ISO 50001

A strategic management tool, like the EMS for the environment with ISO 14001, the EMSn starts with an assessment of the various energy uses. It involves deploying a metering plan (measurement, data collection, analysis, monitoring), which can help identify areas for improvement, such as taking energy efficiency into account in product and equipment purchasing. Once the simplest, most easily cost-saving measures have been implemented, the EMSn can be used to move on to more elaborate operations covering the entire production system. As all the results are quantifiable, the advantage of an EMSn is that it enables you to prioritize the various possible actions according to your company’s financial capacity, context and objectives.

A voluntary approach, the SMEn can lead to AFAQ ISO 50001 certification, which proves to third parties that the effort undertaken is not a self-declaration and will indeed lead to energy savings, thanks to the best practices identified in the standard. Please note: large organizations with current ISO 50001 certification do not need to carry out a regulatory energy audit. You can find out more about our standardization, standards and regulatory watch, training and certification services in our special Energy section.