Exoskeletons: instructions for evaluating interaction with humans

Exoskeletons are designed to reduce the physical load on workers. But are they safe to use? Published in March 2017, the AFNOR Z68-800 agreement makes it possible to assess their interaction with humans. Focus.

Is it safe to use an exoskeleton? It’s not Robocop who has the answer, but AFNOR: published in March 2017, the AFNOR Z68-800 agreement makes it possible to assess the interaction of this type of assistance device with humans.

To get a clearer idea of what’s at stake in this first document on the subject, we went to meet François Marsy, consulting engineer in the fields of innovation and industrial performance, and leader of the AFNOR working group on “Assistive restraint devices (exoskeleton type)”.

What is an exoskeleton? What’s in it for me?

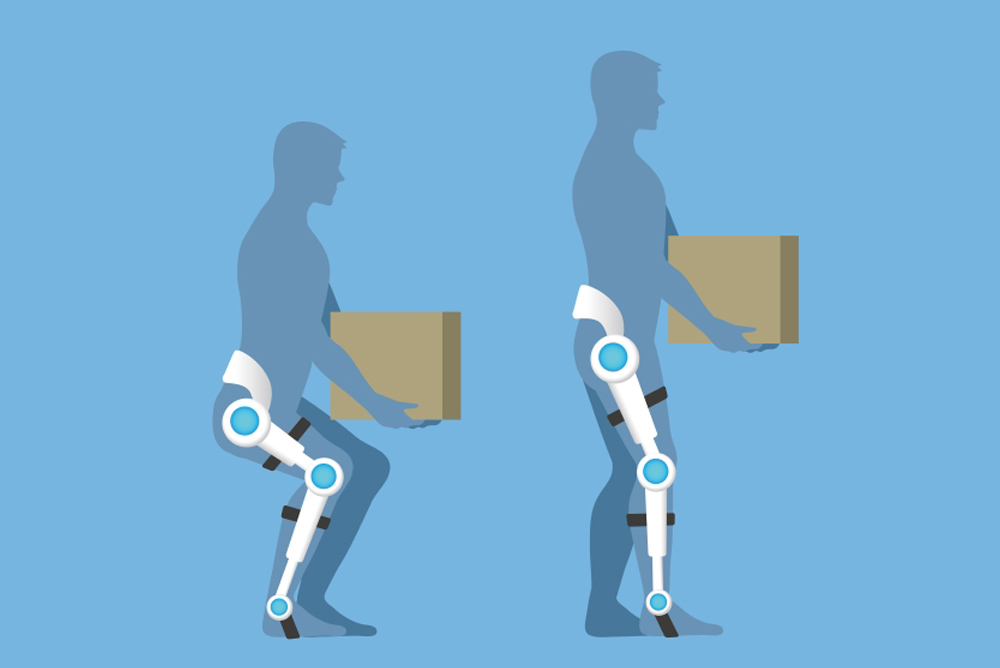

The exoskeleton is a physical assistance device mainly used to support professionals in their efforts. Unlike other external assistance devices, the exoskeleton is worn directly by the operator. So it perfectly matches his gestures.

The exoskeleton is a physical assistance device mainly used to support professionals in their efforts. Unlike other external assistance devices, the exoskeleton is worn directly by the operator. So it perfectly matches his gestures.

As such, it is one of the emerging and innovative solutions for improving posture, reducing physical strain and working in better conditions. In short, to reduce drudgery at work.

Weight, vibrations, adaptation to the employee… this device can present certain constraints. Could the cure be worse than the disease?

The question of the exoskeleton’s side effects, or even harmful effects, is one that current and future users are rightly asking themselves.

Today, an exoskeleton is used either occasionally, or for several hours at a time. For example, in the construction sector, it is available to operators to carry out a difficult task. On the other hand, in mass-production industries, operators are often required to wear it for several hours at a time.

In both cases, the various players expressed the need to be able to better identify the impacts (benefits and constraints) of an exoskeleton on the wearer.

To meet these needs, experts representing users from various fields, the occupational health sector, and exoskeleton designers and integrators have joined forces in a working group set up under the aegis of AFNOR. The primary objective was to analyze this emerging technology from a health perspective. Until now, voluntary standardization on the subject of exoskeletons only covered safety and performance aspects.

What does the AFNOR Z 68-800 agreement published in March 2017 propose?

It’s an instruction manual for assessing the benefits and constraints of the exoskeleton.

It provides everyone with tools and methodological aids for evaluating the use of this device and its interaction with humans.

Exoskeleton designers and future investors and users can thus analyze the impact of the device on the operator’s physical activity (objective methods), and the operator’s feelings and experience (subjective methods). They will also be able to anticipate the biomechanical effects of these exoskeletons on operators, even before they are implemented, or even before they are manufactured (simulation methods).

In addition, the agreement lists the various exoskeleton parameters to be reviewed and offers recommendations on how to carry out this assessment. Representative use cases in various sectors (construction, automotive, military, aeronautics, etc.) illustrate these recommendations. The agreement makes it possible to share best practices among the professionals and players involved.

Above all, this document defines a common language that facilitates exchanges between users, designers and suppliers.

What needs to be planned before operators are equipped? How can we evaluate the use of this device? The Z 68-800 agreement provides a clear answer to these previously unanswered questions.

How can this agreement change the face of the burgeoning exoskeleton market?

The strength of this document lies in the fact that it not only serves as a reference for exoskeleton design, but also as a valuable purchasing aid. It’s important to bear this in mind, as this technology is in full development. Users are primarily industrial, but more and more sectors are expressing their expectations.

The AFNOR agreement comes at just the right time! By proposing best practices and a common language, voluntary standardization gives French players a head start and key tools.