Décryptage – Reindustrialization: the French challenge

Reindustrialization: understanding for action

Forty years after the flight of factories to low-cost countries, how can we reverse the pendulum? With its two feet firmly planted in unbridled globalization, digital transformation and the tertiarization of jobs, France also needs to re-industrialize, as a matter of sovereignty, climate emergency and territorial dynamism. Here’s what’s at stake.

Let’s start with the basics: what does ” reindustrialize ” mean? Is it a synonym for the more commonly used ” relocate “? The answer is no. Reindustrializing is more ambitious than relocating. In fact, relocating to France the factories that were shipped to Eastern Europe or Asia in the 1980s and 1990s would make little sense, given how much manufacturing processes have changed since then, not to mention regulatory requirements. Re-industrialization means above all regaining control and power. It’s a question of sovereignty and democratic health. As geographer Anaïs Voy-Gillis explains in her book Pour une révolution industrielle, the link between industry and democracy is indirect, but it does exist: without industry, you become dependent on other states. The greater this dependence, the more difficult it will be to maintain a democratic process that is neutral and unbiased by foreign economic, military or financial influences. In short, without industry, there can be no sovereign democracy.

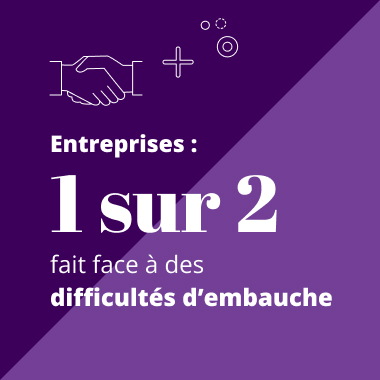

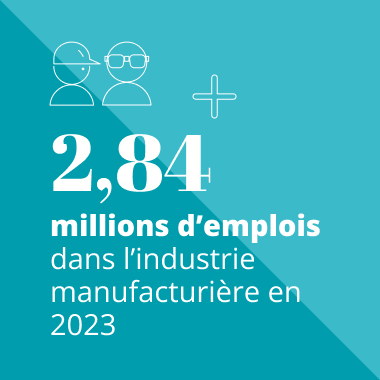

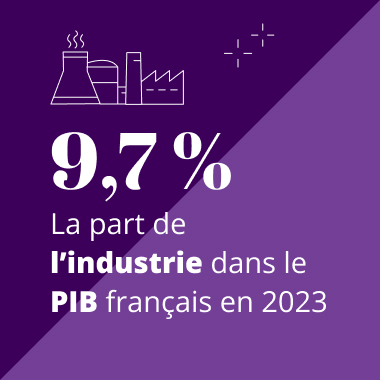

The Forces françaises de l’industrie (FFI), a network of entrepreneurs and investors campaigning for ” made in France”, are saying it loud and clear: reindustrialization means strengthening and sustaining our industrial production. And it needs it! In May 2024, the Direction Générale des Entreprises (DGE), the central service of the Ministry of the Economy and Finance at Bercy, pointed out that ” the deindustrialization movement that took place between the 1970s and the 2010s affected all developed countries, but it particularly affected France, with a drop in industry’s share of GDP from 17% to 11% between 1995 and 2017 “. The ratio has continued to fall, since dropping below 10%(see infographic opposite).

Plant openings and closures: the yo-yo of the thermometer

This downward slide came to a halt in the early 2010s, with an initial reindustrialization drive… whose efforts were disrupted in the following decade by the covid crisis, followed by the war in Ukraine. We have developed an industry barometer based on three new indicators: jobs in industrial trades, the number of active factories, and actual industrial site openings net of closures across the country “, it states on its website . According to these new indicators, by mid-2024, business was picking up: with ” 108,000 additional jobs created in industrial trades in 2022 and projections indicating that France would have 500 more factories in 2023 than in 2016 “.

This downward slide came to a halt in the early 2010s, with an initial reindustrialization drive… whose efforts were disrupted in the following decade by the covid crisis, followed by the war in Ukraine. We have developed an industry barometer based on three new indicators: jobs in industrial trades, the number of active factories, and actual industrial site openings net of closures across the country “, it states on its website . According to these new indicators, by mid-2024, business was picking up: with ” 108,000 additional jobs created in industrial trades in 2022 and projections indicating that France would have 500 more factories in 2023 than in 2016 “.

But that was in the spring of 2024! And since then, FFI has been warning of a situation that is once again becoming delicate: ” We would have liked to have entered the summer of reindustrialization, but winter has returned,” said Laurent Moisson, co-founder of FFI, during a meeting organized at the AFNOR Group offices on January 14, 2025. Against a backdrop of political instability, debt crisis and belt-tightening across the board, ” the manufacturing employment trend has turned red. Many start-ups will not find financing. Some gigafactories will never see the light of day. “points out Olivier Lluansi , author of Réindustrialiser, le défi d’une génération, published by Les Déviations.

Reconciling industry, decarbonization and biodiversity

For the first time since 2016, there were more industrial site closures than openings in France in 2024, despite a strong first half, driven by green industry: ” There are the big names, like Bosch, Caddie, Stellantis and Valeo, which are shedding several hundred employees. And then there are the less visible hundred or so small and medium-sized companies, also caught up in the reindustrialization breakdown. In all, 90 of them closed store in 2024. After Cholet, where the closure of the Michelin plant alone led to the loss of more than 900 jobs, Caen is the agglomeration where the difference between jobs created and jobs lost is the greatest. “summed up Les Echos in November 2024.

For the first time since 2016, there were more industrial site closures than openings in France in 2024, despite a strong first half, driven by green industry: ” There are the big names, like Bosch, Caddie, Stellantis and Valeo, which are shedding several hundred employees. And then there are the less visible hundred or so small and medium-sized companies, also caught up in the reindustrialization breakdown. In all, 90 of them closed store in 2024. After Cholet, where the closure of the Michelin plant alone led to the loss of more than 900 jobs, Caen is the agglomeration where the difference between jobs created and jobs lost is the greatest. “summed up Les Echos in November 2024.

However, there is no shortage of ideas for turning things around. Olivier Lluansi, who was also the first delegate to the Territoires d’industrie, a Saint-Gobain employee, ex-consultant and now lecturer at the CNAM where he works on the decarbonization of our industry, is one of those proposing a roadmap(read his full interview here). Charged with a mission at the end of 2023 by the Ministry of the Economy, his report, submitted the following April, was never made public, due to a lack of agreement on the objective. ” In the summer of 2023, I pointed out that the official target of reaching 15% of industry in GDP by 2035 was out of reach. All the projections on the need for land, skills and training, and even decarbonized energy, indicate that the step is too high. It’s all very well for political ambitions to be high… but they can’t be out of reach. “he asks.

Reindustrialization: focus on small and medium-sized businesses

For him, we’ve come too far: ” We would need to train 200,000 new professionals every year, but the current intake is 60,000 people a year. Similarly, RTE (the electricity transmission network) tells us that, given our ambitions to decarbonize our economy, we can draw up an industrial roadmap for 2035 at 12% or 13% of GDP, but not 15%: we won’t yet have the new nuclear reactors to power these new industries. Do we want a carbon-based reindustrialization? I don’t think so! “The climate must not be sacrificed on the altar of reindustrialization, even though, as seen from France, this notion has the advantage of shortening logistics chains, thus making them lessCO2-emitting, by bringing production centers closer to consumption centers. Natural space, on the other hand, is the subject of lively debate, as demonstrated by the numerous industrial derogations, obtained or requested, to the ZAN (Zero Net Artificialization) principle.

For him, we’ve come too far: ” We would need to train 200,000 new professionals every year, but the current intake is 60,000 people a year. Similarly, RTE (the electricity transmission network) tells us that, given our ambitions to decarbonize our economy, we can draw up an industrial roadmap for 2035 at 12% or 13% of GDP, but not 15%: we won’t yet have the new nuclear reactors to power these new industries. Do we want a carbon-based reindustrialization? I don’t think so! “The climate must not be sacrificed on the altar of reindustrialization, even though, as seen from France, this notion has the advantage of shortening logistics chains, thus making them lessCO2-emitting, by bringing production centers closer to consumption centers. Natural space, on the other hand, is the subject of lively debate, as demonstrated by the numerous industrial derogations, obtained or requested, to the ZAN (Zero Net Artificialization) principle.

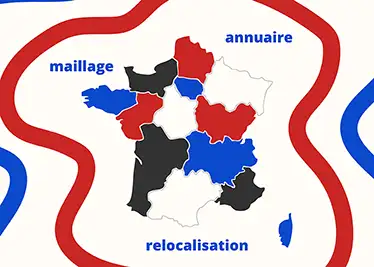

For FFI, two-thirds of the reindustrialization potential lies in the regions. In existing SMEs and ETIs! ” Let’s be clear: reindustrialization isn’t happening in Paris, or only in startups. Nor even in the gigafactories that offer us such fantastic stories. Symbols aren’t everything. It’s thanks to the existing industrial fabric of our thousands of SMEs that we can succeed. “says Olivier Lluansi. Two of these SMEs are Le Parapluie de Cherbourg and Vitabri. The former had a record year in 2024, with 22,000 umbrellas manufactured at the Cotentin-based factory, which employs around 30 people, and 35% growth in online sales. In 2025, founder Charles Yvon launches a new product: an umbrella!

For FFI, two-thirds of the reindustrialization potential lies in the regions. In existing SMEs and ETIs! ” Let’s be clear: reindustrialization isn’t happening in Paris, or only in startups. Nor even in the gigafactories that offer us such fantastic stories. Symbols aren’t everything. It’s thanks to the existing industrial fabric of our thousands of SMEs that we can succeed. “says Olivier Lluansi. Two of these SMEs are Le Parapluie de Cherbourg and Vitabri. The former had a record year in 2024, with 22,000 umbrellas manufactured at the Cotentin-based factory, which employs around 30 people, and 35% growth in online sales. In 2025, founder Charles Yvon launches a new product: an umbrella!  Vitabri is not to be outdone: this Besançon-based SME manufactures a folding tent with rapid deployment (thanks to gas struts), as well as tents and barnums for events, all of which are certified Origine France Garantie . ” Most of our parts used to come from Asia, so we decided to bring them closer together to secure our supplies “, says its manager, Emmanuel Musner(read his full interview here).

Vitabri is not to be outdone: this Besançon-based SME manufactures a folding tent with rapid deployment (thanks to gas struts), as well as tents and barnums for events, all of which are certified Origine France Garantie . ” Most of our parts used to come from Asia, so we decided to bring them closer together to secure our supplies “, says its manager, Emmanuel Musner(read his full interview here).

Mobilizing individual savings and public procurement

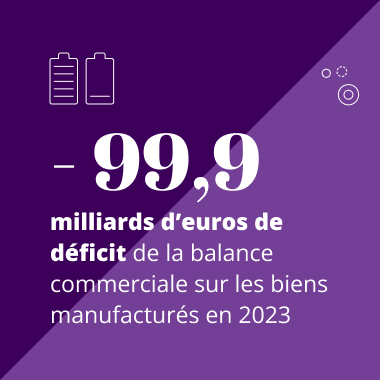

Then there’s the question of money, the sinews of war. Earmarking individual savings and public procurement are two levers regularly cited. To these can be added tariffs, as the new American president has loudly reminded us. But French-style political procrastination is preventing the launch of what would be a Marshall Plan for French industry.

” While France is still debating whether to channel its savings into industry, the Germans are doing it! regularly reminds Laurent Moisson. Why not direct a small part of the 6,500 billion in savings of the French – the second largest savers in the world – towards our reindustrialization? The 2023 Green Industry Act has everything we need to do just that. Meanwhile, the Germans, who are experiencing a period of political instability at least equivalent to our own, are announcing a major measure: a 10% tax credit will be granted to any German or foreign company or group of investors investing in the country’s industrial production. “

” While France is still debating whether to channel its savings into industry, the Germans are doing it! regularly reminds Laurent Moisson. Why not direct a small part of the 6,500 billion in savings of the French – the second largest savers in the world – towards our reindustrialization? The 2023 Green Industry Act has everything we need to do just that. Meanwhile, the Germans, who are experiencing a period of political instability at least equivalent to our own, are announcing a major measure: a 10% tax credit will be granted to any German or foreign company or group of investors investing in the country’s industrial production. “

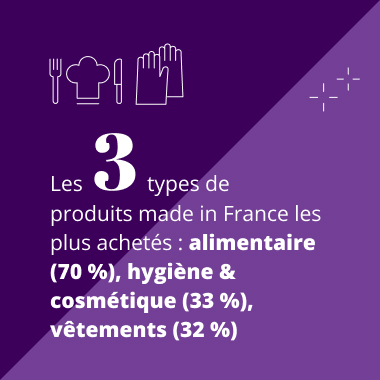

We need to invest 20 billion euros a year for ten years,” adds Olivier Lluansi. It represents 3% of French people’s savings. But we don’t have the “short circuit” between saver and investor to achieve this. Go to your banker and ask for a product that finances your region’s economy: it doesn’t exist. As for public procurement, it’s not patriotic: it buys fewer “made in France” manufactured products than we do as citizens! “

This winter, FFIs took the initiative of raising €50 million to invest in French SMEs via the FFI Croissance fund. ” But much more is needed. If the public authorities created the conditions to encourage life insurance to take an interest in the subject, our reindustrialization would be financed! “says Olivier Lluansi. On June 20, 2024, and again on January 14, 2025, the AFNOR group brought together a group of pioneers convinced that relocation is a team effort. Re-industrialization doesn’t just mean opening factories in France, it also means surrounding oneself with an ecosystem of French suppliers.

“Solutions exist, starting now

Three questions for Olivier Lluansi , who was the first delegate for the Territoires d’industrie program and has just published Réindustrialiser, le défi d’une génération (Les Déviations).

We often talk about percentages of GDP. What other indicators would you suggest to measure reindustrialization?

Olivier Lluansi

Reindustrialization needs to be measured: by GDP points? By trade balance? By industrial jobs? By the well-known indicator of the number of sites opening and closing? In my opinion, the best indicator at the macroeconomic level, the one that enables us to measure the strength of an industry, a country or a continent, is its balance of trade in manufactured goods. Our objective for 2035 in France: to achieve a structurally balanced balance of trade in goods. Since 2005, our trade deficit has fluctuated between -50 and -100 billion euros.

What mistakes should be avoided in public reindustrialization policies?

It would be a mistake, and even a dead end, to neglect the potential of existing SMEs and ETIs and focus solely on gigafactories and startups. I would argue in favor of strengthening the existing industrial fabric, throughout the French regions, which is our best asset. I’d also like to see us be more pragmatic about the rules: when it comes to land, for example, reindustrialization is indeed compatible with protecting our biodiversity and the famous ZAN (zero net artificialisation by 2050), but not with the rules we’ve adopted, which remain blind to the diversity of territories. Sometimes we have land, but not many projects, and sometimes it’s the other way round! The Grand-Est region, for example, is in the process of creating a regional compensation bank. That’s good, but it won’t be enough. The law needs to be rewritten.

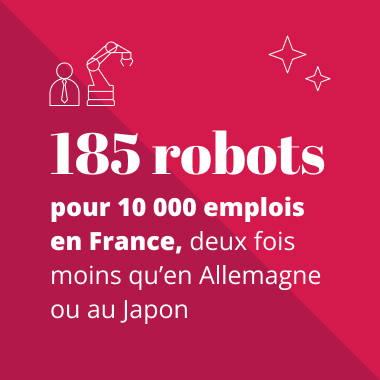

Is there a need for training, particularly in view of the massive retirement forecast?

In fact, we need 110,000 people trained in industrial trades every year, from CAP to bac + 3. We currently train 125,000 people a year, but the tragedy is that half of them don’t join the industry! The attractiveness of industrial professions remains very low: in terms of image, we’re stuck somewhere in the 80s and 90s. The progress made since then, particularly in terms of robotization (less drudgery), is little known. We need a communication campaign similar to what the Army or craftsmen ( France’s ” premier métier “) did twenty years ago, to explain to young people that industry has changed. We also need to tell them that, in a few years’ time, we’re committed to offering them the same flexibility and work-life balance as in the service sector.

A 180-degree turn at Vitabri in Besançon

Having arrived in August 2015, Emmanuel Musner, the boss of Vitabri (55 employees) is the man who turned the company around 180 degrees five years ago now. He recounts what is a reindustrialization success story.

Emmanuel Musner,

A former printer and supplier to Vitabri, the company he now runs in Besançon, Emmanuel Musner brilliantly rose to the challenge of getting the company back on its feet. In 2015, ” this family-run SME was experiencing difficulties at the time. The market for rapid deployment folding tents is ultra-competitive and highly globalized. “he begins. With his team, Emmanuel Musner began by reviewing the strategy: ” The company was struggling to find its feet, selling both low-end and high-end products under the same brand name. I first smoothed over the obstacles, then repositioned Vitabri as a premium brand. And even a premium brand that manufactures in France! “It’s a founding choice that sets in motion a long series of research and decisions. Starting in 2019, Emmanuel Musner and his team will analyze every single part they use to make their tents. “Most of them came from Asia. We chose to bring them closer together in order to secure our supplies”, says the founder, who was vindicated by the covid-19 pandemic, which raised the notion of industrial sovereignty.

“You have to be prepared to lower your margins”.

Today, all parts are designed by the in-house design office, and most of them come from France. This is the case for coated canvas, but also for plastic parts, screws and extruded aluminum tubes for several of the brand’s tents. ” We have also recently invested 400,000 euros to bring our tube machining in-house, develop the skills of our team and offer more and more specific products to our customers,” adds Emmanuel Musner.

Among the pleasant surprises: the fact that made in France does not systematically cost more. It depends on the type of part and the quantity required,” says the manager. But generally speaking, you have to be prepared to lower your margins. It’s not the customer who will finance the transition. For some components, however, the price/quality ratio is so unfavorable that we are forced to continue importing them. “Emmanuel Musner confesses: ” There are days when we feel a little lonely and angry, when we see the unfair competition practiced by certain countries that flood the European market with low-cost products, or the low level of public orders awarded to companies that manufacture in France. All too often, price remains the main criterion of choice. All this is inconsistent with the social and environmental challenges we face. “he says.

“Be patient and play as a team”.

The executive would give two pieces of advice to his peers. The first: patience. ” We want to secure the turn we’ve taken, but selecting new suppliers in France and Europe takes time and energy ,” he says. The second: surround yourself with people. Emmanuel Musner formed a team with his procurement manager, joined the Forces françaises de l’industrie, and drew inspiration from the work of the Convention des entreprises pour le climat. ” Choosing to reindustrialize means thinking in the medium to long term. It means ensuring the company’s long-term future by resolving the problem of dependence on third parties, notably China. “he insists.

Vitabri sells to a wide range of customers: sports federations and brands, event providers, defense, emergency services, market traders, local authorities, craftsmen, rental companies. We’ve never done so well,” concludes Emmanuel Musner. We’ve become more innovative and more agile. We have been awarded ISO 9001 and Origine France Garantie certification, which are highly complementary and guarantee our customers quality tents made in France. I think that certification is a real boost for us. The company will celebrate its thirtieth anniversary in 2026.

Spot your allies

- We can support France’s industrial renaissance by focusing on quality, the environment and local products… and by letting people know about it: that’s what certification is all about, notably with the Origine France Garantie label , which indicates that your product obtains its essential characteristics in France and that at least 50% of its cost price is French.

- We can also, further upstream, get involved in standardization: following on from the Triple E , imagined at the genesis of the Green Industry law in 2023, AFNOR is working on an experimental standard for an industry territory.

- Several regions are starting to set up directories to help manufacturers build up their network of local suppliers; this is the case of Auvergne-Rhône-Alpes, which is devoting over a billion euros to relocation projects, over a period of six to seven years. It undertakes to respond within two weeks to requests from manufacturers.

- The Startups industrielles France (CSI France) collective may be of interest to you if you’re an entrepreneur, as well as BPI France, MEDEF and the French Fab of course, with a particular focus on medium-sized establishments (ETI).

- The national Territoires d’industrie program, launched in 2019, relies on the ANCT and the Banque des Territoires .

- Renaissance industrielle, Business France and the Société d’encouragement pour l’industrie nationale are other sources of information and contacts: reindustrialization really calls for a collective effort.

The 10 elements of the AFNOR toolbox

- ISO 45001 the voluntary standard for occupational health and safety management, for a sustainable, safe working environment.

- The EFQM model The EFQM model: for a commitment to excellence, with an updated 2025 reference framework.

- Origine France Garantie certification attesting that your product obtains its essential characteristics in France, and that at least 50% of its cost price is French.

- ISO 46001 the voluntary standard providing guidelines for the management of water resources. Increasingly strategic for the food industry, for example

- ISO 27001 the voluntary standard for information security management. Cybersecurity has become one of the top risks identified by executives worldwide.

- Tisax the automotive cybersecurity certification standard

- Le Grand défi IA the program to define best practices for deploying trusted AI, entrusted to AFNOR by the public authorities. With manufacturers at the standardization table.

- The DPP is the acronym for the digital product passport, a major issue in the industry.

- NF X32-001 the voluntary standard for implementing a biodiversity protection approach, for reindustrialization without impact. Soon to be ISO standard.

- Risk mapping Risk mapping: an essential exercise to guard against supplier and subcontractor failures and image risks.